Space Simulation

Simulation on earth of the harsh environment experienced in space is critical import for the space industry.

Space Simulation: Testing Equipment and Materials for Space Conditions

Space simulations play a critical role in aerospace research, allowing scientists, engineers, and researchers to test equipment, materials, and even human responses to space-like conditions—without ever leaving Earth. These controlled environments are essential for space mission preparation and risk mitigation.

What Is Space Simulation?

Space simulation involves the use of advanced facilities such as vacuum chambers, thermal vacuum chambers, and other high-fidelity testing environments designed to replicate the extreme conditions found in outer space. These simulations help verify the performance and durability of spacecraft components under realistic conditions.

Importance of Vacuum Testing in Space Simulation

One of the key aspects of space simulation is vacuum testing. As spacecraft ascend through Earth's atmosphere, pressure drops dramatically. At an altitude of 50 km, the atmospheric pressure falls to about 1E-3 mbar, and by the time the craft reaches the Kármán line—100 km above sea level and the widely accepted boundary of space—the pressure is approximately 1E-6 mbar.

Replicating these low-pressure environments on Earth is essential for ensuring that materials and systems can function in space. Testing in vacuum conditions helps identify vulnerabilities and optimize designs for extreme conditions, including temperature fluctuations and the absence of atmospheric pressure.

Vacuum Measurement and Control in Space Simulation

Accurate vacuum measurement and control are critical components of space simulation testing. These systems ensure that the pressure within simulation chambers is maintained at levels that match the desired test conditions. High-precision vacuum gauges and control systems allow researchers to simulate various altitudes and space environments with reliability and repeatability.

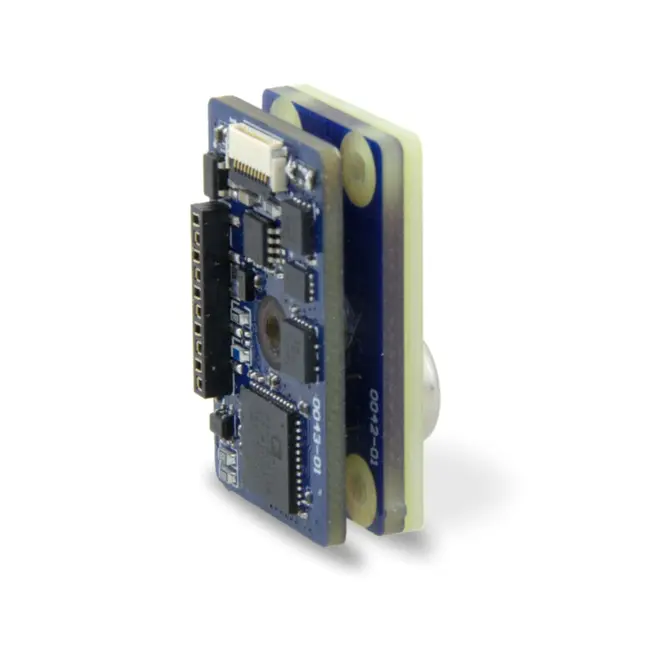

iVacSens™

The best choice for a high level of integration where geometric space is limited. Wide-range MEMS Pirani with measurement capability down to 1E-6 mbar.

Get in touch with the Sens4 team for more information

We highly appreciate questions, feedback, and customer dialogue.