Rethink Vacuum Gauging

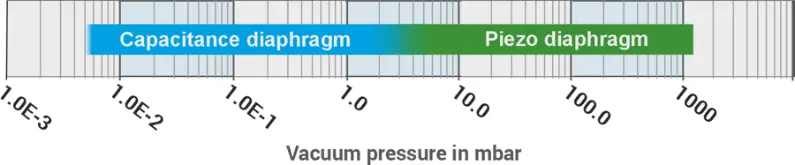

The VDM-5 DiCAP™ is an innovative multi-sensor vacuum gauge and is the ideal choice for upgrading the performance of traditional Pirani gauge applications or as a cost-optimized all-in-one solution for applications that use separate capacitance manometers and Pirani gauges.

Enabling Use in Demanding Applications

For applications involving exposure to corrosive or aggressive gases, the DiCAP™ is available with a conformal protective coating that acts as an effective barrier.

The VDM-5 DiCAP™ transducer series offers optional protective layers made of ceramic or Parylene to safeguard sensor materials against corrosion or oxidation.

Ceramic provides exceptional corrosion resistance and is a trusted material for vacuum sensor diaphragms in capacitance diaphragm gauges.

Parylene, a unique polymer with superior corrosion-resistant and hydrophobic properties, is especially suitable for medical applications such as lyophilization and hydrogen peroxide sterilization.

For vacuum processes where particulates may pose a threat to gauges, DiCAP™ transducers are available with a protective baffle to block macroscopic particles. Combined with protective coating options, these transducers are designed to perform reliably in challenging vacuum environments.

Analog Output

A wide selection of analog output scaling options to emulate other vendors’ vacuum gauges and transducers is available. An optional secondary analog output enables external monitoring of both the full-range vacuum pressure and the pressure signal relative to atmospheric pressure

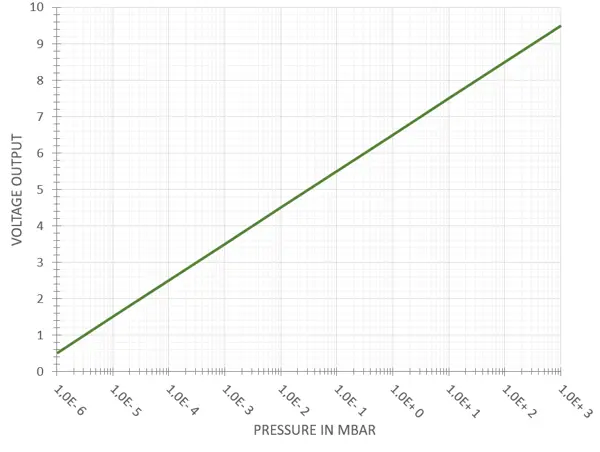

The analog output voltage provides a signal for external readout or controls. The VDM-5 offers as standard a voltage output signal of 1VDC/decade mbar, Torr, or Pascal. The analog output configuration can easily be changed by use the the digital interface.

Connect Digital

The RS-232 and RS-485 serial interfaces can be used to transfer pressure and temperature measurement data to external equipment.

The digital interface enables diagnostics, predictive maintenance, service, calibration, setpoint configuration, analog output scaling, and the acquisition of real-time vacuum pressure measurements for on-screen visualization.

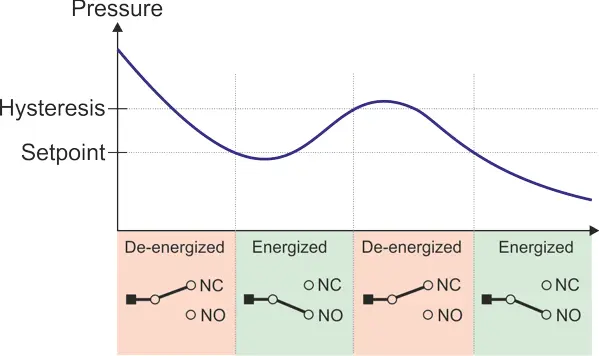

Reliable Setpoint Relay Control

The three independent solid-state switch relays can be used to control external equipment, such as pumps, valves, and safety interlock circuits.

Unlike electro-mechanical relays, solid-state relays provide greater reliability and faster switching speeds, with arc-free contacts and no EMI (electromagnetic interference) during switching.

The VDM-5 DiCAP™ relays are engineered for longevity and are UL-listed, CSA-recognized, and EN/IEC 60950-1 certified, ensuring high confidence in controlling critical vacuum processes and high-cycle applications.

Other Vendor Compatibility

The VDM-5 DiCAP™ transducer is available with pin compatibility, analog voltage pressure signal emulation, and digital protocol emulation with vacuum transducers and transmitters from other vendors.

These emulation features enable quick, seamless performance upgrades of legacy micro-Pirani transducers, allowing a transition to next-generation vacuum transducers without changing cabling and system equipment software.

The VDM-5 DiCAP™ will provide enhanced measurement performance in many applications when replacing legacy vacuum gauges and transducers.

The other vendor emulation also provides compatibility with other vendors' controllers and display units.

Applications & Markets

The VDM-5 DiCAP™ is designed for reliable measurement and control of advanced vacuum processes and is suitable for a wide range of applications in industry and science. A wide selection of VDM-5 configurations is available to meet different requirements across various applications.

Destillation

Measurement and surveillance of insulation vacuum in Hydrogen storage tanks and supply lines.