Technical White Paper

By Ole Wenzel, CEO Sens4 A/S

Abstract

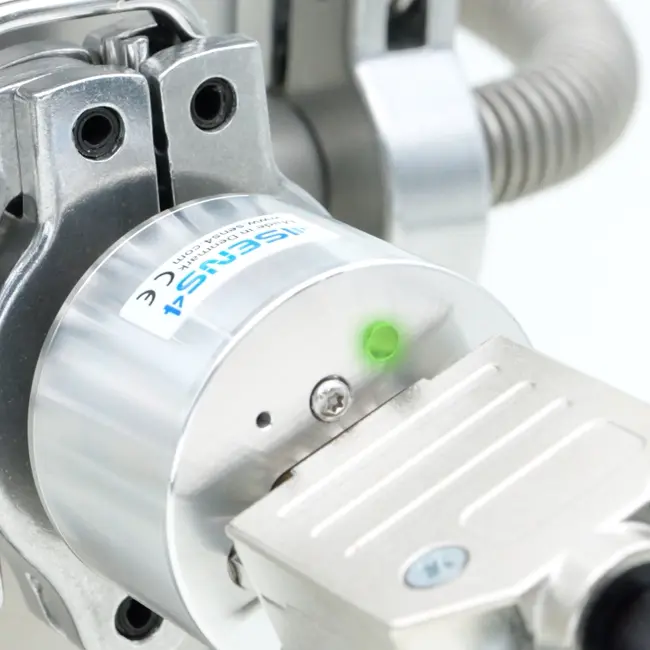

Load-lock systems play a critical role in semiconductor manufacturing by enabling wafer transfer between atmospheric and vacuum environments without venting the main process chamber. Accurate and reliable pressure control during each phase of the load-lock cycle that includes venting, evacuation, stabilization, and transfer is essential to maintain process yield, minimize contamination risk, and reduce cycle time. This white paper examines the evolution of pressure measurement and control technologies used in load-lock systems. It presents a detailed technical overview of multi-sensor architectures that combine MEMS Pirani, absolute piezo resistive, and capacitance diaphragm sensors to cover the full vacuum range and enable precise gauge pressure control relative to ambient barometric conditions. Advanced features such as autonomous solid-state switching, programmable setpoints, and robust analog and digital I/O interfaces are also discussed. These advancements enable engineers to design reliable, and efficient load-lock systems for demanding semiconductor and industrial vacuum applications.

Download PDF White Paper

Load-lock Pressure Control in the Semiconductor Industry

Stay ahead in vacuum measurement technology — sign up for the Sens4 newsletter to get the latest innovations, application insights, and product updates delivered to you:

Unsubscribe at any time.